Modern battery chargers are no longer simple plug-and-play boxes—they are smart, efficient, and adaptive. Two key technologies that make this possible are PWM (Pulse Width Modulation) and MCU (Microcontroller Unit). But how do they work together, and why do they matter?

In this post, we’ll break down how PWM and MCU combine to deliver intelligent charging—protecting your battery, increasing efficiency, and extending product life.

What is PWM?

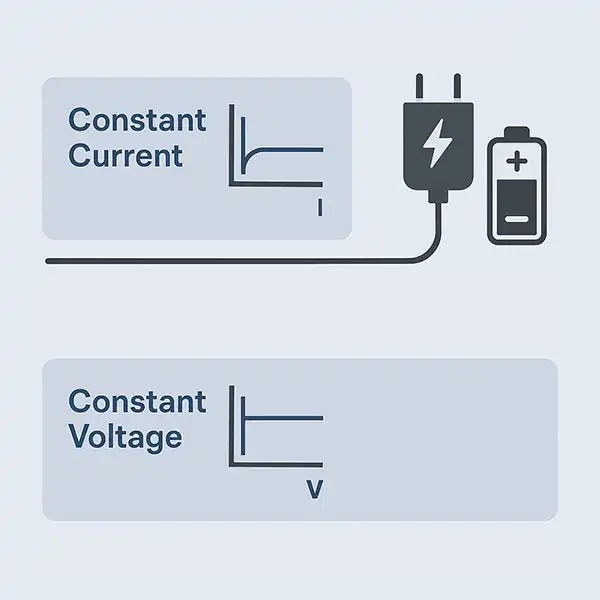

Pulse Width Modulation (PWM) is a switching technique used to regulate voltage and current by rapidly turning the power on and off at high frequency. By adjusting the duty cycle (the “on” time), the output power is finely controlled.

Benefits of PWM in chargers:

- Efficient power conversion

- Reduced heat generation

- Smooth current control to protect batteries

What is an MCU?

The Microcontroller Unit (MCU) is like the brain of a smart charger. It constantly monitors various battery parameters—voltage, temperature, current, charge state—and adjusts charging behavior accordingly.

What the MCU controls:

- Charging stages (bulk, absorption, float, etc.)

- Protection functions (overvoltage, short circuit, temperature)

- Communication with BMS via CAN/RS485 (in advanced systems)

How PWM and MCU Work Together

When combined, PWM and MCU create a closed-loop system:

- The MCU collects data from sensors or battery feedback.

- It makes decisions based on programmed algorithms (e.g., when to enter float stage or reduce current).

- It adjusts the PWM signal accordingly—changing the duty cycle to modify current/voltage output.

- This cycle repeats in real-time, ensuring optimal charging conditions throughout the process.

For example, when the battery nears full capacity, the MCU reduces the PWM duty cycle to prevent overcharging and heat buildup—extending battery life.

Why It Matters for Your Battery

Smart chargers with PWM + MCU offer:

- High efficiency (less energy wasted as heat)

- Accurate charging curves that match battery chemistry

- Advanced protection from electrical faults

- Compatibility with lithium batteries and communication protocols

Learn more about Battery Management Systems (BMS) and how they interact with intelligent chargers.

Final Thoughts

If you’re using a LiFePO4, AGM, or lead-acid battery, a charger with both PWM and MCU is the best choice in 2025. It’s the perfect blend of power and precision, giving you safe, smart, and long-lasting charging.

Ready to upgrade? Visit our Intelligent Charger Collection to explore PWM-controlled, MCU-integrated models built for performance and safety.